Liquid Mosquito Filling and Capping Machine (XFY-4)

Description

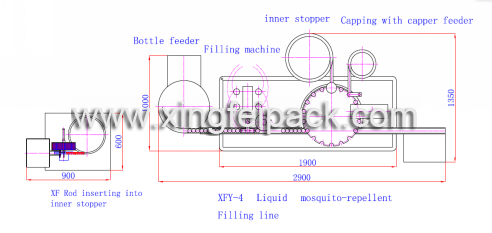

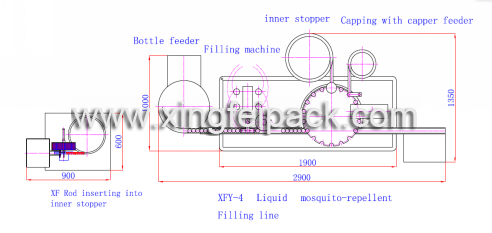

XFY-4 liquid mosquito filling and capping machine is designed for liquid mosquito repellent incense filling and sealing. It adopts automatic filling with 4-head, automatic sortering inner stopper with rod, automatic cap bottle, automatic covering and capping.

Features

1. It adopts PLC controlling for the entire process and touch screen operation with high degree of automation.

2. Liquid mosquito filling and capping machine has the functions of precise measure, no bottle no inserting, no bottle no capping, stable running, and beautiful surface.

Material of main spare parts

Dosing pump: 316L

Contact part with bottle: 304# stainless steel or nylon

Table and side structure: 304# stainless steel

Parameters

|

Model

|

XFY-4 Liquid Mosquito Filling and Capping Machine

|

|

Capacity

|

2400 bottle/h

|

|

Specification

|

40 ml plastic bottle

|

|

Filling precision

|

0 to 2%

|

|

Power

|

2 kW

|

|

Machine size

|

2900 × 1200× 1600 (including bottle feeder)

|

Main parts of Liquid Mosquito Filling and Capping Machine

|

No

|

name

|

Type or material

|

Supplier

|

|

1

|

PLC

|

DVP30SS11T2

|

DELTA of Taiwan

|

|

2

|

Touch screen

|

DOP-B05S100

|

DELTA of Taiwan

|

|

3

|

Frequency converter

|

S310-201-H1BCD75

|

Dongyuan of Taiwan

|

|

4

|

Load cell

|

BW200-DDT

|

Banner of USA

|

|

5

|

Precision indexing boxes

|

RTT80-12-2:1

|

China

|

|

6

|

Other electrical and pneumatic parts

|

|

Zhengtai

|

|

7

|

Divide plate

|

Nylon

|

Lantoky pack

|

|

8

|

bottle feeding system

|

component

|

Lantoky pack

|

|

9

|

Inner stopper system

|

component

|

Lantoky pack

|

|

10

|

Cap press system

|

component

|

Lantoky pack

|

|

11

|

Motive system

|

component

|

Lantoky pack

|

|

12

|

Structure and table

|

component(A3)

|

Lantoky pack

|

|

13

|

Side structure

|

component(304#)

|

Lantoky pack

|

Exploded View of Mosquito Repellent Incense Filling Line

Stopper Inserting Machine (XF)

Description

Stopper inserting machine is a specialized machine used in liquid mosquito repellent incense filling line to press the long rig into inner plastic stopper. Inner stopper are lined by an oscillator and then be sent one by one to the gaps of an intermittent moving equi-index plate. When the plate turns to the top, rigs in the rig lining unit will be pressed out one by one into their corresponding inner stoppers through a cylinder, and the inner stoppers will fall into the collecting plate again. The rig length (to be put into the inner corks) can be adjusted individually.

Features

Our stopper inserting machine features precise measure, stable running and beautiful surface.

Material of main spare parts

Part contact with the rod and inner stopper: 304#stainless steel or nylon

Table and side structure: 304#stainless steel

Parameters of Stopper Inserting Machine

|

Capacity

|

2400 to 3000 bottle/h

|

|

product

|

rod and inner stopper

|

|

Precision

|

≥ 99.5%

|

|

Power

|

1kW

|

|

Machine size

|

900 × 600 × 1600 mm

|

Main parts of Stopper Inserting Machine

|

No.

|

Name

|

Type or material

|

Supplier

|

|

1

|

Frequency converter

|

S310-201-H1BCD75

|

Tecoof Taiwan

|

|

2

|

Load cell

|

BW200-DDT

|

Banner of USA

|

|

3

|

Precision indexing boxes

|

RTT80-12-2:1

|

China

|

|

4

|

pneumatic system

|

|

Airtac of Taiwan

|

|

5

|

Other electrical and pneumatic parts

|

|

Zhengtai

|

|

6

|

Divide plate

|

Nylon

|

Lantokypack

|

|

7

|

Cap feeding system

|

component

|

Lantokypack

|

|

8

|

Cap press system

|

component

|

Lantokypack

|

|

9

|

Bottle feeder

|

component

|

Lantokypack

|

|

10

|

Motive system

|

component

|

Lantokypack

|

|

11

|

Structure and table

|

component(A3)

|

Lantokypack

|

|

12

|

Side structure

|

component(304#)

|

Lantokypack

|