Automatic Petroleum Jelly Filling Machine

Description

Automatic petroleum jelly filling machine adopts Taiwan Delta PLC and touch screen. Variable-frequency governor uses the brand from Taiwan TECO. Photoelectric amplifier and optical fiber uses the brand from Korea Atonics.

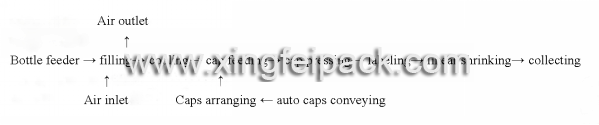

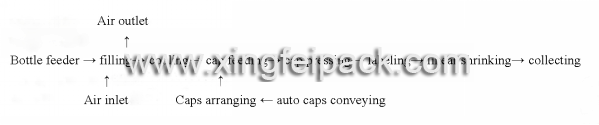

Working Process of Vaseline Filling Capping Machine

Technical Parameters of Automatic Petroleum Jelly Filling Machine

|

Production Capacity

|

1500 to 2700 bottles/hour (weight 25g to 450g ) (6 head)

|

|

Type of bottles

|

plastic bottles

|

|

Weight

|

25g/ 100g/ 250g/ 450g

|

|

Filling precision

|

±1%

|

|

Filling Temperature

|

60℃ to 90℃

|

|

Filling Pipe

|

hard stainless steel pipe & soft stainless steel pipe

|

|

Cooling time

|

1min to 2min

|

|

Cap quantity in the caps feeding machine

|

>600 caps

|

|

Type of adhesive labeling machine

|

front, back and top labeling

|

|

Type of shrinking

|

Linear, sealing and cutting, shrinking, cooling

|

|

Power

|

380V, 50Hz, three-phase four-wire system

|

|

Total power

|

18.5kW + 12 kW

|

Main Components of Automatic Petroleum Jelly Filling Machine

|

PLC, Touch screen

|

Delta from Taiwan

|

|

variable-frequency governor

|

TECO from Taiwan

|

|

photoelectric amplifier and optical fiber

|

Atonics from Korea

|

|

Other components

|

Schneider from France

|

Machine list of Vaseline Filling Capping Machine

|

No.

|

Products

|

Quantity

|

Remarks

|

|

1

|

XF-bottle feeder

|

1

|

|

|

2

|

Hot liquid Transfer Pump

|

1

|

|

|

XF-GZ-6 automatic liquid weighing and filling machine

|

1

|

With warm keeping device

|

|

Change over parts

|

1

|

One set of measuring pump

|

|

Stainless steel heating and warm keeping liquid storage

|

1

|

300 L

|

|

3

|

S shape air cooling machine

|

1

|

|

|

4

|

automatic caps loading and pressing machine

|

1

|

|

|

Change over parts

|

3

|

mould

|

|

automatic caps conveyor

|

1

|

|

|

5

|

XF-TB-3 adhesive labeling machine

|

1

|

|

|

6

|

Automatic linear cutting heating and shrinking machine

|

1

|

(optional)

|

|

7

|

Conveyor belt

|

3 meters

|

|

|

8

|

Roller type Conveyor Belt

|

1meter

|

|